Schaeffler Lifetime Solutions Roadshow

Maintenance of rolling bearings is an important task!

Unplanned machine downtime is expensive and causes sudden increases in workload in the workplace.

With Schaeffler Lifetime Solutions, we offer you a wide range of solutions and products to ensure that the maintenance of your systems runs smoothly and predictably.

Get to know our entire product portfolio at first hand during your visit on board the Schaeffler Lifetime Solutions truck.

Our stop at Schaeffler Bulgaria

30.06.2023

Don’t let things slow down your daily business.

As part of the Schaeffler Roadshow, learn about innovations which make your work easier: from condition monitoring, through lubricant supply to assembly and dismantling - the Schaeffler Lifetime Solutions allow you to concentrate on your day-to-day business, without worrying about downtime and the associated costs.

In the truck you will experience - interactively - not only how breakdowns can be dealt with, but how they can be avoided altogether.

Register now and get on board - we look forward to seeing you!

The truck will stop here:

Industry Zone

9160 Devnya

To contact us:

Mr. Alexej Gescheff

geschaex@schaeffler.com

+ 359 888570561

Find out all about

Innovative

monitoring solutions

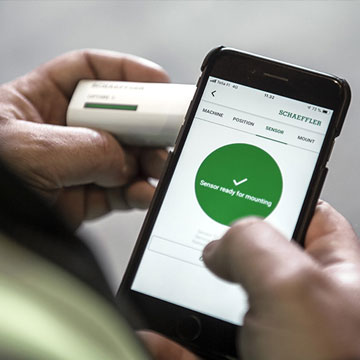

With our OPTIME sensors you can monitor hundreds of units within a few hours. The expandable system works for almost all types of units and detects potential damage, imbalance and misalignment weeks in advance.

During your visit on board Schaeffler Lifetime Solutions truck, you will learn all about our portfolio of condition monitoring technologies. For more information on condition monitoring, read our white paper, Is machine monitoring worthwile?.

Smart

lubricators

THE OPTIME C1 is an easy-to-use and cost-effective solution for automatic single point lubrication. OPTIME C1 extends the Schaeffler OPTIME system developed for the condition monitoring of rolling bearings and integrates the lubricators of the CONCEPT1 series.

During your visit on board Schaeffler Lifetime Solutions truck, you will learn everything about our lubricants and lubricators. Another little tip for lubrication, with the Schaeffler Grease App you can easily determine the correct ARCANOL rolling bearing grease, the correct initial greasing quantity and the correct relubrication interval as well as the relubrication quantities.

Precision

maintenance tools

During your visit on board Schaeffler Lifetime Solutions truck, try for yourself and see how easy and simple it is to mount a bearing with our assembly tools.

With our OPTIME sensors you can monitor hundreds of units within a few hours. The expandable system works for almost all types of units and detects potential damage, imbalance and misalignment weeks in advance.

During your visit on board Schaeffler Lifetime Solutions truck, you will learn all about our portfolio of condition monitoring technologies. For more information on condition monitoring, read our white paper, Is machine monitoring worthwile?.

THE OPTIME C1 is an easy-to-use and cost-effective solution for automatic single point lubrication. OPTIME C1 extends the Schaeffler OPTIME system developed for the condition monitoring of rolling bearings and integrates the lubricators of the CONCEPT1 series.

During your visit on board Schaeffler Lifetime Solutions truck, you will learn everything about our lubricants and lubricators. Another little tip for lubrication, with the Schaeffler Grease App you can easily determine the correct ARCANOL rolling bearing grease, the correct initial greasing quantity and the correct relubrication interval as well as the relubrication quantities.

During your visit on board Schaeffler Lifetime Solutions truck, try for yourself and see how easy and simple it is to mount a bearing with our assembly tools.

Then sign up to our industrial customer portal, Schaeffler medias and stay up-to-date.